At times I don't know whether to laugh or cry. Six Sigma Stupidity just keeps on giving. Recent weeks have produced some absolute gems from consulting Masters of Six Sigma Stupidity.

We've all heard about how Six Sigma was based on the ridiculous claim that all processes shift/drift +/-1.5 sigma in 24 hours and that this claim was founded on the height of a stack of discs ("Benderizing").

Until now the +/-1.5 sigma drift/shift was just the figment of a mind in fairyland. Thanks to Masters of Six Sigma Stupidity, we now have empirical evidence! Trumpets! Fanfare! So, on to our first Six Sigma Gem.

Gem #1"We were just reviewing our own experience with shift and it pretty conclusively exists in our processes." Believe it or not, this was presented as "evidence" for Six Sigma. We have real world "proof" of the shifty Six Sigma. (Names are withheld to protect the guilty.)

Adding to the hilarity, a second black belt consultant later independently made an almost identical statement.

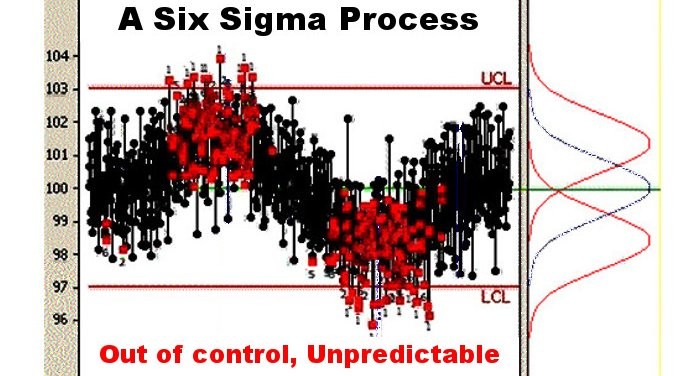

In other words, Masters of Six Sigma Stupidity have discovered that the processes they are "improving" for clients, are wildly out of control, as in the image below. Why should anyone be surprised that a survey showed 80% of Six Sigma projects fail (of those brave enough to admit failure)

It's not rocket science but the Six Sigma gang just doesn't seem to get it. When a process drifts or shifts, it will produce points outside control limits. That is, it is out of control. Something is wrong with the process. There is a special cause(s) at work. There is no limit to the magnitude of special causes. An out of control process is unpredictable. It may produce defects no matter where specification limits are set.

How many thousands of clients have been fed the farce that all processes shift +/-1.5 sigma every day?

No wonder Dr Wheeler, the world's greatest process statistician, calls Six Sigma "goofy".

Many folk have said they feel offended by my use of the word "stupid". Strangely, no one has objected to "goofy". Do these folk really believe the claim that all processes in the world are controlled by a psychologist's stack of discs, is not stupid? Practitioners of Six Sigma political correctness, claim "incorrect" is more correct than stupid, as in "incorrect as a donkey" rather than "stupid as a donkey". We of the antipodes call stupid what it is. Please note once again, that it is Six Sigma that is stupid. Some of those promoting Six Sigma have been quite clever to fool so many people for so long with such blatant nonsense.

Gem #2The second Six Sigma Stupidity Gem that has been thrown at me several times, always very sagely, as though it is second nature to a Master of Stupidity: "It's a shift, not a drift". No matter how many times I hear this, it leaves me gobsmacked.

Let me be clear. The +/- 1.5 sigma is pure farce. It is a fabrication. It doesn't exist.

The +/-1.5 sigma is part of the lunacy of the psychologist who created Six Sigma; the man who said: "I am not an engineer. I have to admit I did not know what [Mr] Bill [Smith] was talking about". At various times, he tried to prop up his rubbish and claimed it to be based on:

- The height of a stack of discs.

- The supposed maximum possible special cause

- A "dynamic mean offset"

- Power curves

- A Chi Square "correction" ... boy, does that sound impressive.

- An Excel spreadsheet doddle

I must admit that it is difficult to pick the most stupid, but that stack of discs is right up there. As I have shown in great detail, all are pure poppycock. The +/-1.5 sigma is no more a shift than a drift than it is a pink elephant in a tutu riding a tricycle. Everything based on the +/-1.5, that is, the 3.4 dpmo, Six Sigma Tables, and Six Sigma itself, is as ludicrous as that pink elephant holding a magic fairy wand in its trunk.

We may conclude that these consultants in shifts and drifts either have the intelligence of a Patagonian Clupeomorph, or more likely, these folk are aware that if they admit the truth, Six Sigma and their income stream, collapses.

Gem #3Hilarity No3 is the Six Sigma bloke who advised that if you reduce variation in a process, you should always remember to broaden specification limits afterwards. Of course, the creator of Six Sigma advised Six Sigma can't help with process improvement. This is precisely what Professor Deming said. "Analysis of variance, t- test, confidence intervals, and other statistical techniques taught in the books, however interesting, are inappropriate." Mr Bill Smith urged we should follow Dr Deming's advice. For process improvement you need to rely on that part of Six Sigma which its creator said is "80% TQM". The TQM part can definitely help reduce variation.

Perhaps Six Sigma bloke was simply following Mr Bill Smith's advice that a way to improve quality is to broaden specification limits. Anyone who doesn't understand why this is so stupid, should contact their customers and tell them that despite your no longer meeting their requirements, things aren't as bad as they seem, because you use Six Sigma.

Gem #4Funny Four is consultants putting letters after names to denote 2 week courses in Six Sigma Stupidity that they have bought from some other guy with a 2 week certificate of Stupidity. I assume they do it to try to appear important. I can't wait to see a "Sam Stupid FAC, IC, BM , MB, SSWBGB" (First Aid Certificate, Induction Certificate, Bronze Medallion, Merit Badge, Star Stamp on Wrist for Being a Good Boy.)

Gem #5Finally, and it's so laughable it's not funny at all, but I had a fellow tell me "How do you expect to make a living if you don't promote Six Sigma?" Honesty and integrity have gone out the window, along with quality.

No, the death of quality is not funny.

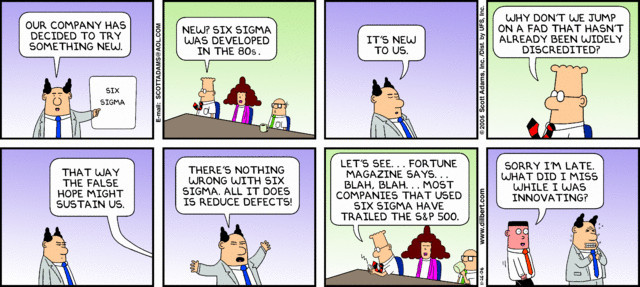

Fortunately there's always Dilbert to get us laughing again about Six Sigma Stupidity.

by Dr Tony Burns BE (Hon 1) PhD (Chem Eng)

by Dr Tony Burns BE (Hon 1) PhD (Chem Eng)