The Six Sigma Scam has produced volumes of nonsense relating to "Cost of Quality". ASQ for example, claims "true quality-related costs as high as 15-20% of sales revenue, some going as high as 40% of total operations". Perhaps they are alluding to the massive cost of Ford's 22% defective product from "successful" Six Sigma projects.

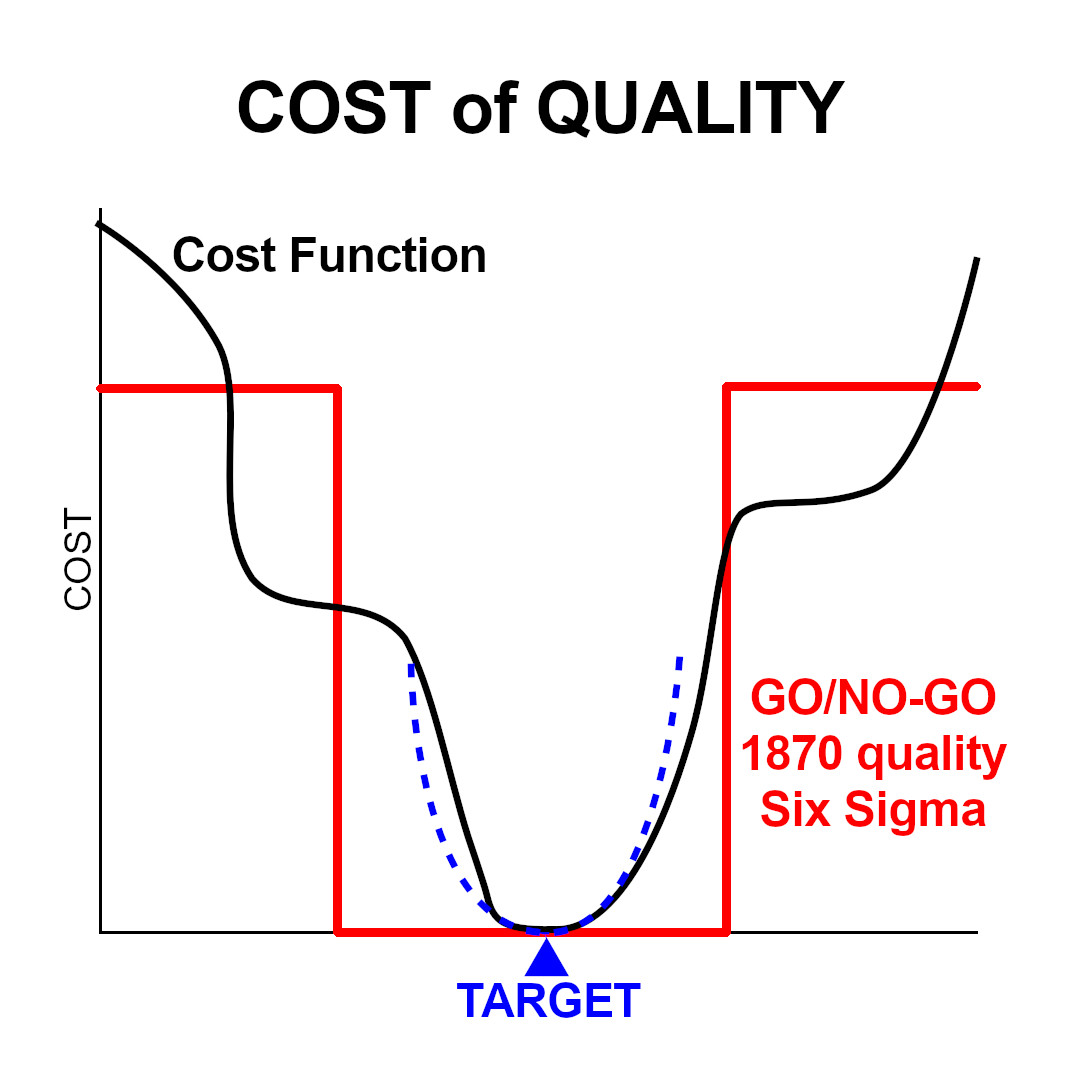

The rhetoric around cost of quality demonstrates a failure to understand what quality means. The rhetoric derives from a fixation on the 1870's definition of quality, where product was deemed to either conform to specification, or not.

Such misunderstanding is illustrated in the Ford transmission study, half a century ago. https://tinyurl.com/5n8b4bas Ford was aware the Japanese quality was far superior because Japan did NOT focus on defects as Ford did.

Contrary to ASQ's baseless hype, we have seen with GE, Motorola, Boeing, Ford, IBM, Home Depot and 3M, that Six Sigma does NOT "reduce cost of quality" nor does it increase "customer satisfaction".

TAGUCHIProfessor Genichi Taguchi provided a way to view Quality and the costs associated with it. His method forms the basis of modern quality.

Taguchi suggested that there is some ideal target value for any parameter. Costs increase in some way with deviation from this target. Cost may be anything from increased wear of finished components, to scrap and rework, to component concentrations, to loss of revenue from "seconds".

Taguchi did NOT suggest a quadratic function to represent costs, as is commonly shown. He simply suggested that there is some arbitrary function for ALL costs, that has a minimum when the product or service is on target.

BROOK TAYLORThis cost function can be approximated about the target value, using a Taylor expansion. A Taylor series will approximate any function about a point, using a polynomial. If we consider the first 3 terms of the series, the first term is the minimum and its coefficient can be set to zero. The derivative of the second term will be zero at the minimum and it too can be set to zero. That leaves the 3rd term, the square of the difference between the parameter value and its target value.

DATA DISTRIBUTIONIn other words, total costs will be minimized when a process is operated with MINIMUM VARIANCE and ON TARGET.

SUMMARYKEEP IT SIMPLE